After years of development, the lithium battery industry has formed a complete industrial chain with a high degree of specialization. Do you know how the lithium battery is made?

The following is a brief introduction to the production process of lithium batteries:

1. Chemicals preparation.

The electrode active material, binder, solvent, etc. are mixed together, fully stirred and dispersed to prepare a slurry.

2. Coating.

The slurry is intermittently and evenly coated on the surface of the conveying current collector and dried to form a pole piece roll of positive and negative electrodes, respectively.

3. Cold press.

After the positive and negative electrode plates are coated, the positive and negative materials are relatively sparse, and a certain pressure needs to be given to the pole pieces to compact the positive and negative electrode materials to a certain range.

4. Cut into pieces.

According to the size of battery, the positive and negative electrodes need to be cut into corresponding widths.

5. Winding.

A small strip of positive and negative pole pieces and a separator are wound to form a bare cell.

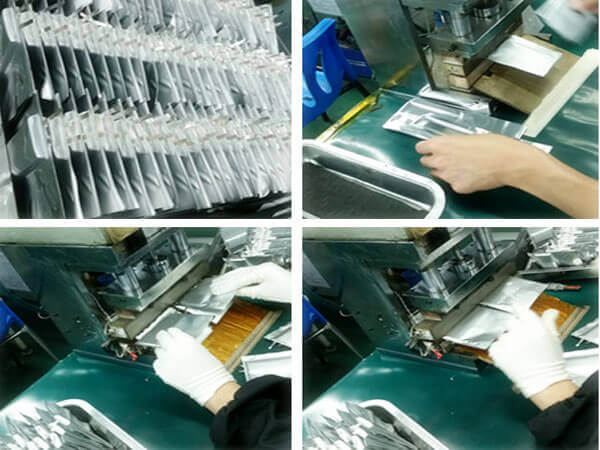

6. Install into the shell, spot welding, vacuum drying.

Wrap the bare cell with aluminum foil, and heat encapsulate the top and sides. In addition, the vacuum and high temperature baking is carried out to dry a small amount of moisture, so that the performance of the lithium battery is guaranteed.

7. Fill the liquid.

Add electrolyte to the battery cell and seal the battery cell completely.

8. Cell activation.

The assembled cell is given a certain current to activate the positive and negative materials inside, and the battery can only be used as a power source after it is activated.

9. Capacity test.

In the manufacturing process, the actual capacity of the battery is inconsistent due to the process, and the battery is classified according to capacity through a certain charge and discharge test.

10. Forming.

Final processing of battery cell shape.

The production process of high-quality lithium batteries is very rigorous, because only in this way can the quality be guaranteed. However, the quality of lithium batteries on the market is uneven, so when you choose lithium batteries, don’t be greedy for cheap, try to choose the brand as possible, reliable quality, guaranteed after-sale!